Product Introduction

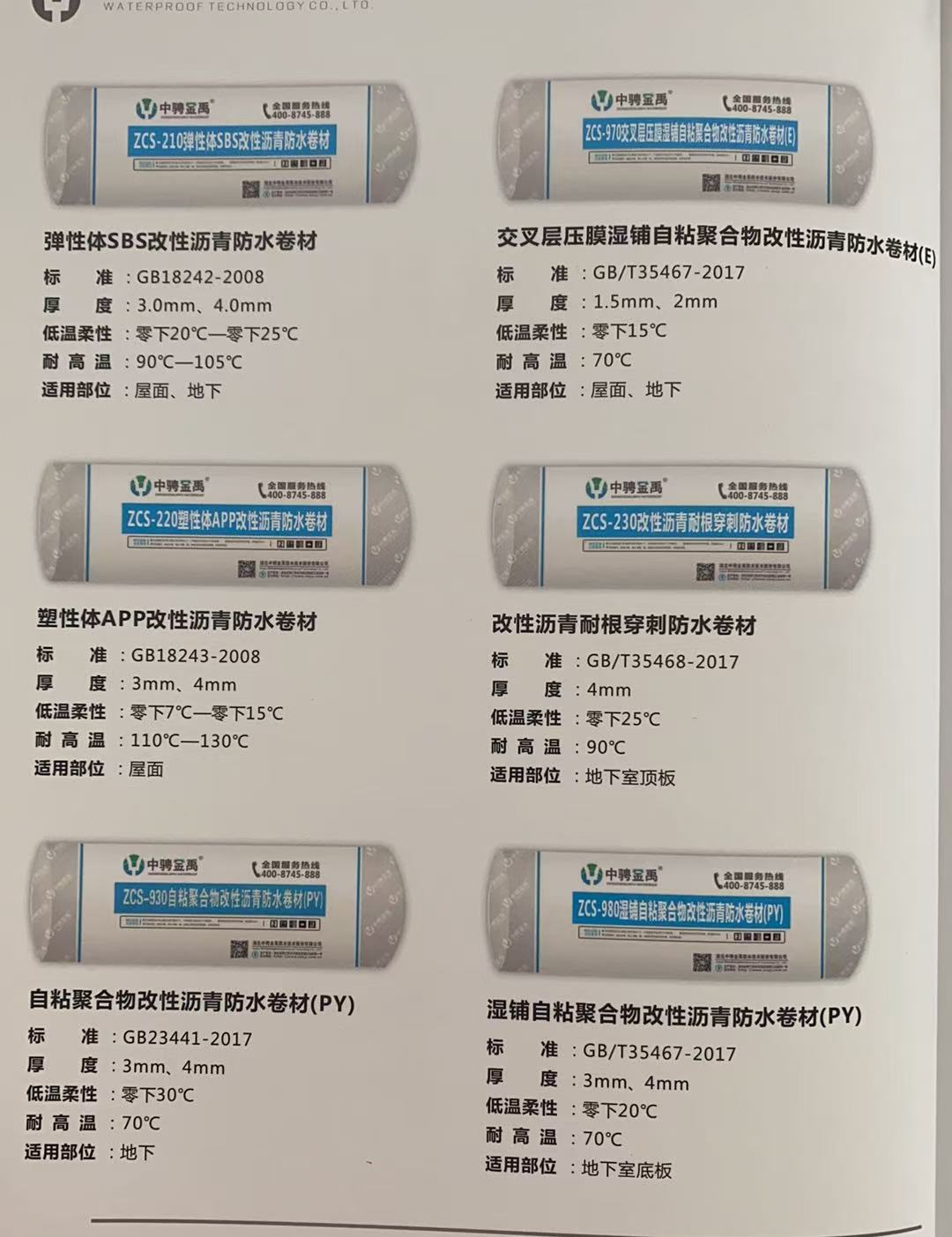

The product is a waterproof membrane made of long fiber polyester felt (PY) as the base material, styrene-butadiene-styrene (SBS) thermoplastic elastomer as petroleum asphalt modifier, and polyethylene membrane (PE) as the insulation material on both sides.

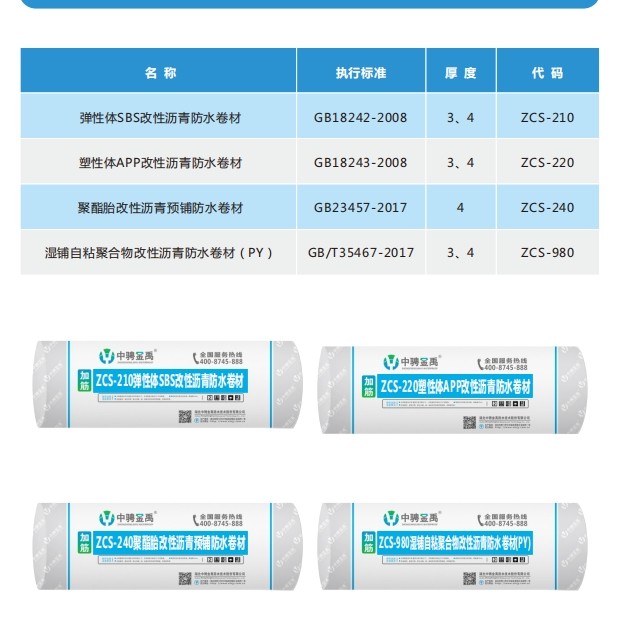

Product Specifications:

According to physical properties, it is divided into type I and type II

Thickness/mm Thickness 3.0 4.0

Width/m Width 1.0

Length/m Length 10 7.5

Fetal basis PY G PYG

Surface material PE S M

Thickness 3.0mm 4.0mm

Width 1000mm

Remarks PY-polyester tires; G-fiberglass tires; PYG-glass fiber reinforced polyester tires; PE-polyethylene film; S-fine sand;

M-mineral granules/schist

Product Features

●Good extensibility, weather resistance, and flexibility;

●Strong adhesion, high plasticity, high strength, strong adaptability, impact and wear resistance;

●Excellent high and low temperature resistance, can be used in hot and cold areas, especially suitable for cold areas;

●High-strength tire base, large material thickness, puncture resistance, corrosion resistance, mildew resistance, fatigue resistance;

●Easy construction, hot melt construction, tight and reliable lap joints;

●Shale cladding material has excellent aging resistance and can be exposed.

Scope of Application

Engineering waterproofing, lake prevention and waterproofing of roofs and basements of various industrial and civil buildings, as well as waterproofing of cold storage, fire pools, swimming pools and other structures;

Waterproofing of municipal and water conservancy facilities such as subways, legs, highways and bridges, landfills, sewage treatment, and canals;

Construction method

The hot melt method is adopted. A construction method in which a flame gun is used to bake the hot melt adhesive at the bottom of the coil for bonding. Before construction, it is necessary to evenly coat the base layer treatment agent (full adhesion method), and then bounce the line according to the construction direction, determine the coil paving position, unfold the coil at the position of the elastic line to release stress, roll the coil from both ends to the middle, bake the bottom layer of hot melt glue of the coil with a flame gun, pave the coil from the middle to both ends, and compact it with a pressure roller while laying the side, remove the air, so that the coil and the base layer are firmly bonded, the lap part should overflow with hot melt modified asphalt, and the lap part of the coil overlap with fine sand and mineral particles should be sandbed treatment. The detailed nodes should be treated with additional treatment, the lap and end should be sealed, and the protective layer of the polyethylene film cladding membrane should be set up according to relevant specifications and design requirements after passing the acceptance.

Clean the base surface" pre-lay the membrane, release the stress elastic line positioning" apply cold bottom oil, use flamethrower, "pave the coil by hot adhesion", use a pressure roller to compact the membrane and squeeze out the air, inspect and test the waterproof layer that has been constructed

Executive Standard

The physical and mechanical properties comply with the requirements of GB18242-2008 "Elastomer Modified Asphalt Waterproof Membrane"

Product Specifications:

According to physical properties, it is divided into type I and type II

Thickness/mm Thickness 3.0 4.0

Width/m Width 1.0

Length/m Length 10 7.5

Fetal basis PY G PYG

Surface material PE S M

Thickness 3.0mm 4.0mm

Width 1000mm

Remarks PY-polyester tires; G-fiberglass tires; PYG-glass fiber reinforced polyester tires; PE-polyethylene film; S-fine sand;

M-mineral granules/schist

Executive Standard

The physical and mechanical properties comply with the requirements of GB18242-2008 "Elastomer Modified Asphalt Waterproof Membrane"