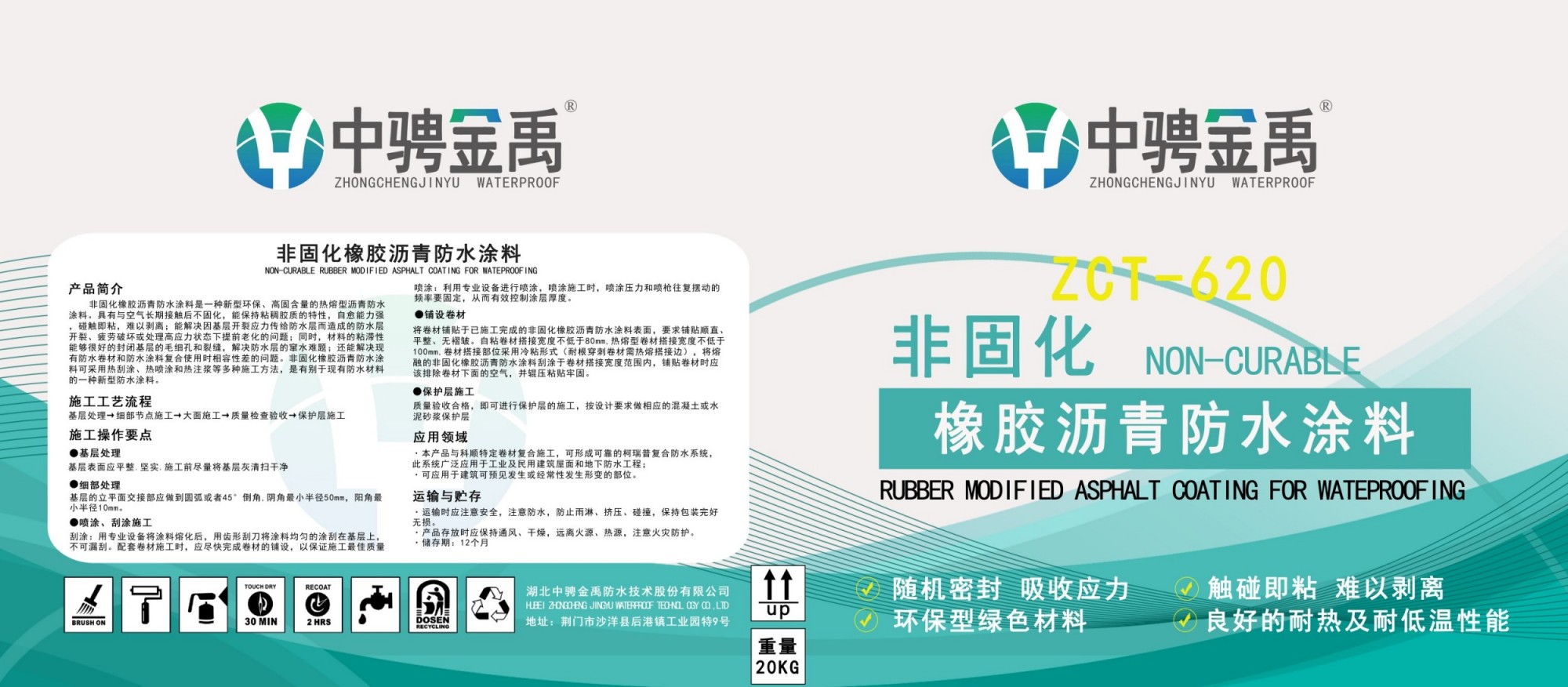

Product Overview Froouct Introduction

This product is a new type of waterproof coating formulated with natural rubber, high-quality petroleum asphalt as the base material, adding functional polymer modifiers and special additives as the modified materials, maintaining a sticky paste for a long time at room temperature, and the viscosity decreases after heating, showing a flowable liquid state.

Product Specifications:

1.5mm/2.0mm

Product Features

● Anti-sagging: no cracking at low temperature, no flow at high temperature.

● Never cure: It is a creep product, with a solid content of more than 98%, almost no volatiles, and always maintains elastoplastic colloids in the application state. 0 Super adhesion performance, can be applied on wet substrates, can come into contact with any foreign objects.

● Excellent self-healing function, when the waterproof layer is damaged by external forces, the damage point will not expand, and it can repair itself, which greatly improves the reliability of the waterproof layer. Excellent elongation performance, more than 1000% elongation, will not affect the waterproof function of the waterproof layer due to the misalignment of the base layer.

● Excellent weather resistance, can resist acid, alkali, salt corrosion, high and low temperature resistance, does not contain organic solvents, is non-toxic, has no irritating odor, can be applied in an environment above -10 °C, is an environmentally friendly waterproof coating.

Scope of Application

●It is suitable for the base layer with large undulations and stresses and parts that are foreseeable and frequently deformed.

●It is especially suitable for projects that cannot use open flame construction, mechanical construction and cold adhesive construction.

Construction method

The grassroots level requires clean, flat, solid, and ignorant water.

● Coating Construction:

(1) Use professional equipment to melt the paint, and use a scraper to evenly scrape the paint on the surface of the base layer according to the thickness requirements. If the supporting coil construction is completed, the coil laying should be completed as soon as possible to ensure the best quality of construction, and the lap part is also bonded with paint.

(2) During spraying construction, the spraying pressure and the frequency of the left and right swing of the spray gun should be fixed, so as to effectively control the thickness of the paint.

(3) After the coil is paved, it is required to be straight, flat, dense, and without wrinkles, and the lap width of the coil is 80mm (self-adhesive lap) and 100mm (hot melt lap)

(4) After the waterproof layer is accepted, the protective layer can be constructed.

Clean the base surface> apply on-site hot-melt non-curing rubber asphalt coating> apply waterproof materials, lay protective isolation layers> and inspect and test the waterproof layer spraying method and scraping method after construction.

Executive Standard

JC/T2428-2017 "Non-curing rubber asphalt waterproof coating"