Product Overview:

This product is a reinforced self-adhesive waterproof membrane made of long-fiber polyester felt as the tire base, self-adhesive polymer modified asphalt as the dipping material, polyethylene membrane, fine sand or isolation material as the surface material, and silicone oil anti-stick isolation layer.

Implementation standards

GB/T23441-2009 "Self-adhesive polymer modified asphalt waterproofing membrane"

Product Specifications:

According to physical properties, it is divided into type I and type II.

Applications:

It is suitable for waterproofing non-exposed roofs, basements, interiors, tunnels, subways and municipal projects in industrial and civil buildings.

It is suitable for waterproofing special structure roofs, such as wooden roofs.

It is especially suitable for waterproof projects such as oil depots, chemical plants, textile factories that are not suitable for open flame construction.

Product features:

· It has high tensile strength and large elongation, and has strong adaptability to expansion and contraction or cracking and deformation of the base layer.

· It can form a high-strength waterproof layer and has strong resistance to pressure water.

· It has good fatigue resistance, puncture resistance, and corrosion resistance.

· Good bonding performance and self-healing function, the coil is fully bonded to the base layer, and the seam itself is bonded to the same life as the coil.

Construction method

Paste method

On the dry, flat, dust-free base layer, apply the base layer treatment agent first, and after drying, remove the separator film on the self-adhesive surface and directly bond it with the base layer.

Implementation standards

GB/T23441-2009 "Self-adhesive polymer modified asphalt waterproofing membrane"

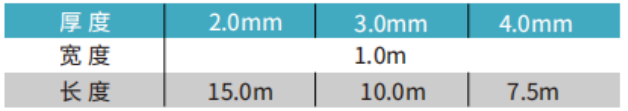

Product Specifications:

According to physical properties, it is divided into type I and type II.