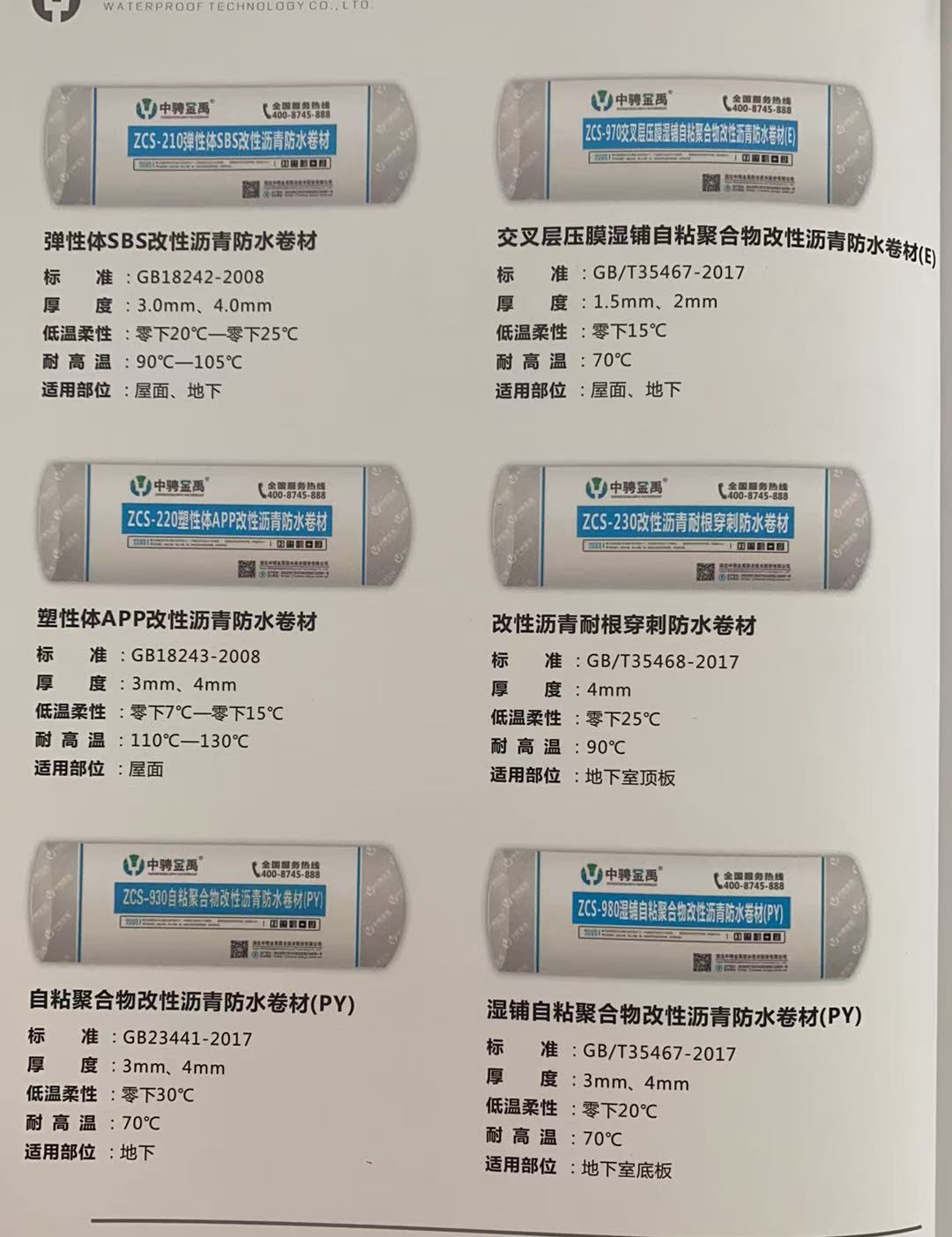

Product Overview Froouct Introduction

Self-adhesive polymer modified asphalt waterproof membrane (PY class) is a self-adhesive polymer modified asphalt polyester tire waterproof membrane made of filament polyester felt as the tire base, tackified polymer modified asphalt as the dipping material, the upper surface is covered with polyethylene membrane fine sand, shale, aluminum foil or separator film as the isolation layer, and the lower surface is coated with silicon separator film as the anti-stick layer.

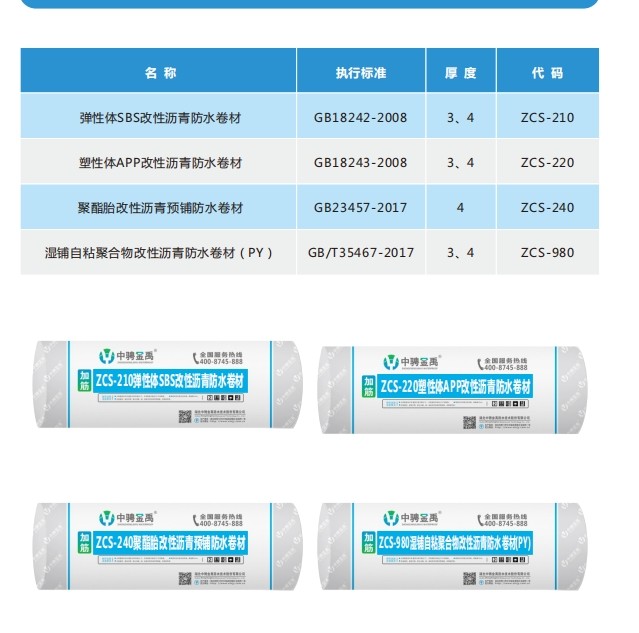

Product Specifications:

Product type: Type I, Type II

Upper surface material Polyethylene film (PE), filmless double-sided self-adhesive (D), fine sand (S)

Width 1000mm 2000mm

Thickness: 2.0mm, 3.0mm, 4.0mm, 3.0mm, 4.0mm

Product Features

● Cold construction: no open flame, no adhesive, energy saving, environmental protection, low carbon, economical;

● Excellent bonding performance: Excellent bonding performance with the base layer, avoiding the occurrence of water channeling. It has a self-healing function, and the seam itself can be bonded with the same life as the coil;

● High tensile strength, large elongation, strong puncture resistance and corrosion resistance; Excellent low-temperature performance;

● Wide coil material construction loss is less and construction is more convenient.

Scope of Application

● Non-exposed roofing and underground engineering waterproofing. waterproofing of municipal projects such as canals and swimming pools; @ Waterproofing of open-cut subway projects, etc.;

● It is especially suitable for waterproofing projects where open flames cannot be used; Excellent low temperature performance is more suitable for use in cold regions.

● Type I products are suitable for underground and roof waterproofing of general and mid-range construction projects;

● When used for the main material of underground engineering, the original degree of the whole material used in a single exhibition should be 23mm; The thickness of the standard material used in double exhibition should be 23mm and 3mm

Construction method

Cleaner surface >> Pre-laid coil, release stress elastic line positioning >> Coating the base spreading treatment >> Cold adhesive method Pave the coil >> Use a pressure roller to compact the coil and squeeze out the air >> Inspect and test the waterproof layer after construction

Executive Standard

GB23441-2009 "Self-Adhesive Polymer Modified Asphalt Waterproofing Membrane"

Product Specifications:

Product type: Type I, Type II

Upper surface material Polyethylene film (PE), filmless double-sided self-adhesive (D), fine sand (S)

Width 1000mm 2000mm

Thickness: 2.0mm, 3.0mm, 4.0mm, 3.0mm, 4.0mm

Executive Standard

GB23441-2009 "Self-Adhesive Polymer Modified Asphalt Waterproofing Membrane"