Product Overview Froouct Introduction

This product is based on polymer homogeneous sheet and coated with self-adhesive adhesive on the surface, which is suitable for waterproof membrane with post-pouring concrete or cement mortar mixing structure. The self-adhesive layer of the membrane has the function of self-healing, and after reacting and consolidating with the liquid concrete slurry, it forms a gap-free combination between the waterproof layer and the concrete structure

Product Specifications:

Width specification/m 1.2/2.0

Thickness specification/mm 1.2/1.5/1.7

Length specification/m/roll 20

Scope of Application

●Rail transit engineering: high-speed rail, subway, intercity rail and other tunnel projects;

● Environmental protection projects: landfills, sewage treatment plants, tailings treatment plants;

●Underground engineering: basements and underground comprehensive pipe galleries of civil and industrial buildings:

●Water conservancy projects: anti-seepage projects such as reservoirs, artificial lakes, and canals.

Product Features

●It has the characteristics of aging resistance, high viscosity of self-adhesive film, strong crack resistance, heat resistance, low temperature resistance, corrosion resistance, and good water resistance;

●The self-adhesive film layer directly forms a reliable full adhesion with the concrete, effectively inhibiting the phenomenon of water channeling;

●Multiple construction processes, convenient and efficient;

●The lap method is flexible, the lap is firm and reliable, and the durability is good; Cold construction, solvent-free, avoid environmental pollution, safe and environmentally friendly.

Construction method

Tunnel pre-paving anti-adhesive construction

A fixed gasket is installed → a elastic line in the tunnel vault, a laying of HDPE waterproof membrane and a waterproof membrane mechanically fixed (hanging sling) → lap treatment→ binding steel bars → pouring concrete

Basement pre-paving anti-adhesive construction and plane construction process

Clean up the base layer → elastic line→ lay pre-laid anti-adhesive waterproof membrane→ lay HDPE waterproof membrane→ lap treatment→ binding steel bars→ pouring concrete façade construction process

Clean the base layer → elastic line→ lay pre-laid anti-adhesive waterproof membrane→ mechanically fix waterproof membrane→ lap treatment→ bind steel bars→ pour concrete

According to different requirements such as engineering structure, engineering category, engineering design, and use standards, wet laying or pre-paving construction methods can be selected.

Pre-laying method:

●Coil pre-laying: Measure and cut the product, and the self-adhesive layer of the coil is isolated from the paper side towards the structural layer, and the other side is facing the base layer, and it is pre-laid on the cushion, protective wall, underground diaphragm wall or pile row. (The polymer coil with geotextile surface material used in the underground tunnel is directly hung on the pre-fixed hook)

●Coil seam: The coil seam adopts a cold self-adhesive method, and the reserved separator film on the self-adhesive edge of the seam can be peeled off and pasted directly to form a completely sealed waterproof system.

●Membrane anti-adhesion: When pouring structural concrete, the coil can cross-link and mew with the flowing concrete to form a strong adhesion. In this way, the membrane is bonded to the concrete building structure, thus forming a combination of waterproof membrane and the building structure without gaps.

●If you need to tie the steel bars, you can tie them directly, and there is no need to pour mortar and fine stone concrete for the waterproof membrane as a protective layer.

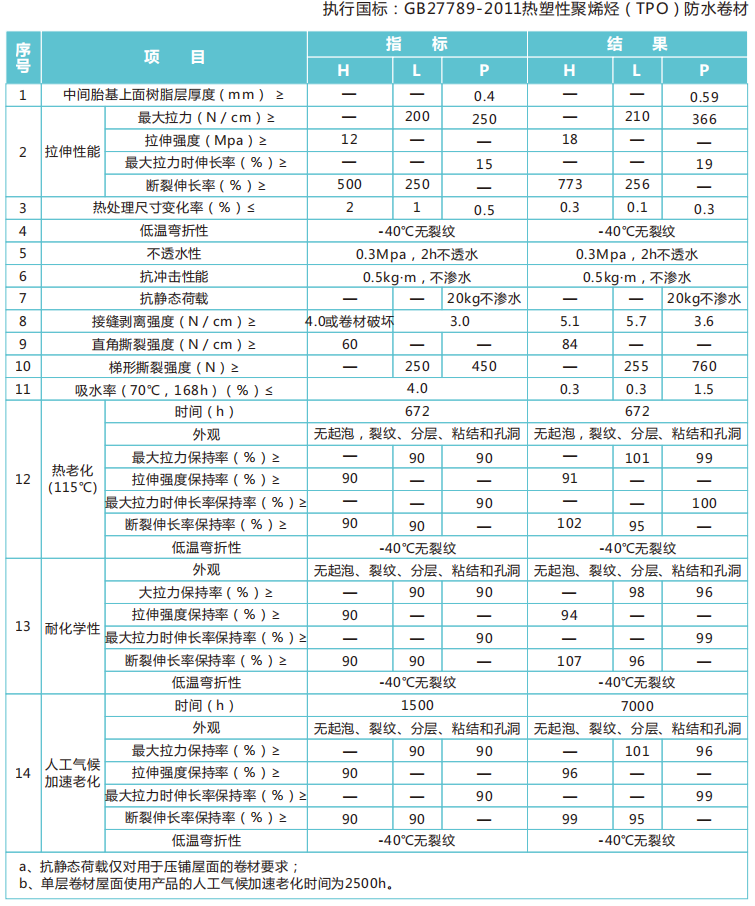

Executive Standard

GB/T 23457-2017 "Pre-laid waterproof membrane"