Product Overview Froouct Introduction

This product is a waterproof material made of polyvinyl chloride (PVC) resin as the main raw material and additives such as plasticizers, stabilizers, antioxidants, and anti-aging agents. The material has the characteristics of high strength and elongation, and also has good flexibility, can be used exposed, and the root puncture resistant PVC membrane has the dual functions of waterproof and preventing plant roots from penetrating.

Product Features

●The product has a long service life, high tensile strength, large elongation, and can effectively resist the damage of the waterproof layer caused by structural deformation;

●Strong root puncture performance, which can effectively prevent plant root puncture;

●Superior aging resistance, low heat treatment size change rate, excellent wind lifting performance, suitable for exposed single-layer roofing system: the joints are firm and reliable, safe and environmentally friendly

●It has good low temperature flexibility and high temperature resistance, and good weather resistance.

●Aging resistance and long service life.

●High tensile strength, high elongation rate, and small change in heating size.

●Effectively resist the erosion of harmful chemicals and industrial pollutants, and the abrasion-resistant and root-puncture-resistant membrane resists perforation, effectively preventing plant roots from passing through. And does not affect the normal growth of the plant.

●Rich color and good plasticity.

●Good low temperature flexibility, adapt to the large temperature difference of the environment.

Product Specifications:

Width specification/m 2.0

Thickness specification/mm 1.2/1.5/1.8/2.0

Big Wine Nine Children Da Zhou Jiuding Length specification/m/roll 20 or above

Fiber inner reinforcement tape fiber backing membrane (GL). Homogeneous coil (H), fiber-backed coil (L), fabric inner reinforced coil (P), glass fiber inner reinforced coil (G), glass

According to whether the material is suitable for exposed use, it can be divided into: exposed use and non-exposed use

Thickness 1.2mm 1.5mm 1.8mm 2.0mm

Scope of Application

●Waterproofing projects for basement roofs and roofs of various industrial and civil buildings, including planted roofs, concrete flat roofs, sloped roofs, light steel structure roofs and exposed single-layer roofs;

● Metro, highway and railway tunnels, bridges, artificial lakes, civil air defense projects, etc.;

●Waterproof projects such as large grain depots, beam yards, and landfills.

Construction method

Mechanical fixation method: that is, the construction method of fixing the waterproof membrane on the roof base layer by using fixing parts

Base layer treatment Laying vapor insulation layer Fixed insulation layer Pre-laid waterproof membrane Fixed waterproof membrane Welded waterproof membrane

Full adhesion method: that is, the construction method of using adhesive to bond all the waterproof membranes to the roof base

Base layer treatment, elastic line positioning, pre-laid waterproof membrane, painted adhesive, compacted, exhausted, hot air welding

●Full adhesion method:

The roll uses adhesive to fix the waterproof membrane on the base layer.

●Mechanical fixation method:

The construction method of fixing the waterproof membrane on the base layer is adopted.

●Empty paving topping method:

The construction method of laying waterproof membrane on the roof foundation and laying the pressing material on it.

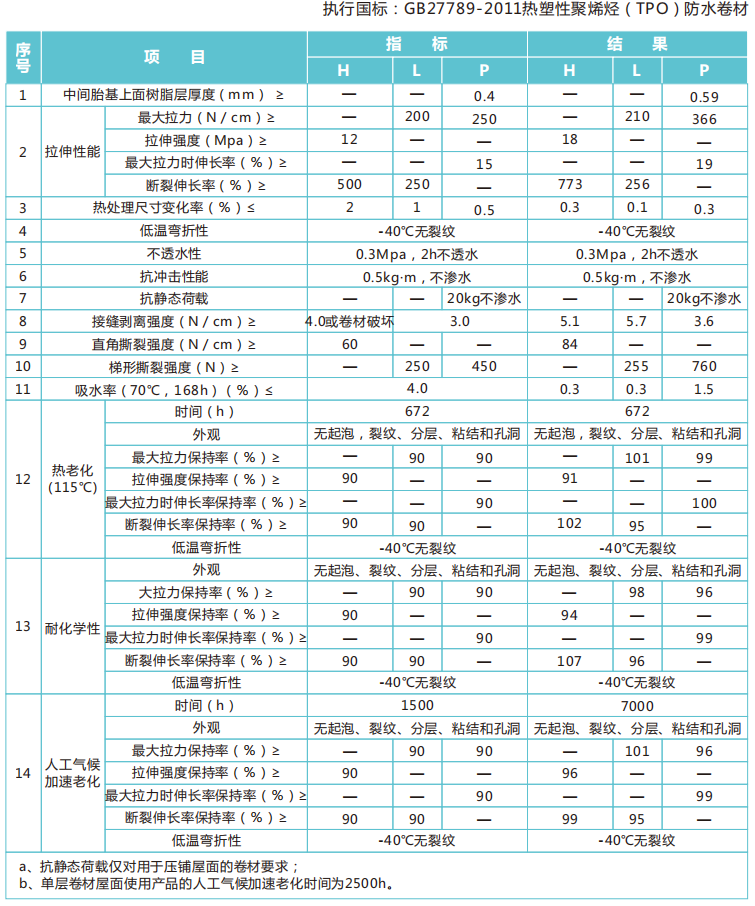

Executive Standard

Executive Standard-GB12952-2011 (Polyoxyethylene (PVC) Waterproofing Membrane》