Froouct Introduction

The product uses patented technology to composite thermoplastic polyolefin (TPO) and polymer asphalt self-adhesive layer into one, forming a composite waterproof membrane with a weather-resistant, durable and high-strength TPO layer on the upper surface and a self-adhesive asphalt adhesive layer with excellent bonding properties on the lower surface. It not only inherits the excellent weather resistance, chemical resistance and environmental protection of TPO materials, but also combines the good bonding sealing and construction convenience of the asphalt self-adhesive layer, eliminating the need to remove the original asphalt waterproof layer when renovating the asphalt roof, and shorten the construction period. This product has a national invention patent (ZL2023202431879)

Product Features

●Patented innovative structure: The unique "TPO + polyester tire + self-adhesive asphalt glue" composite structure integrates the advantages of multiple materials.

●Excellent weather resistance: The TPO surface has excellent UV resistance, high and low temperature resistance (-40°C ~ +120°C), ozone resistance, aging resistance, and long service life.

●High strength and damage resistance: Polyester tire base gives the product extremely high tensile strength, elongation, tear and puncture resistance, which can effectively resist the deformation of the base layer and external damage.

●Excellent bonding and sealing: The self-adhesive asphalt adhesive layer can form a long-lasting and firm "skin-like" full bond with the clean and solid cement concrete base, with good sealing and eliminating the hidden danger of water leakage.

●Moisture base adaptability: The specially formulated self-adhesive layer has relatively low humidity requirements for the base layer, and can effectively bond on the slightly damp base surface, improving construction efficiency and adaptability.

●Convenient and efficient construction: cold construction, no open flame, no hot melt, just tear off the isolation film, rolling can be bonded. Greatly reduce construction safety risks, reduce environmental pollution, and improve construction speed.

●Outstanding environmental performance: TPO material itself is non-toxic and odorless, and can be recycled; Cold adhesive construction has no smoke and harmful gas emissions, which meets the requirements of green building and environmental protection.

●Self-healing performance: The asphalt self-adhesive layer has a certain self-healing ability for micropunctures.

●Double waterproof guarantee: The TPO film layer and the self-adhesive layer together form a double waterproof barrier, which is more reliable.

Scope of Application

Waterproofing of all kinds of new and maintenance construction projects

Building roof: concrete flat roof, slope roof, planting roof, light steel roof, metal roof, etc.

Underground engineering: waterproof and moisture-proof basements, tunnels, pipe galleries, culverts, etc.

Other fields: subways, bridges, water treatment facilities and other engineering parts that require high waterproof requirements and need to be weather-resistant and durable.

Construction method

1. Base layer treatment: The base layer should be solid, flat, clean (no floating ash, oil stains, debris), dry or slightly damp (need to meet the requirements of the product and specifications for the humidity of the base layer). Yin and yang angles, pipe roots and other parts should be made into arcs or obtuse angles.

2. Additional layer treatment: lay additional layer membranes at detailed nodes (such as yin and yang corners, pipe roots, water outlets, gutter cornices, deformation joints, etc.), with a width of not less than 500mm.

3. Stretch the baseline line: Bounce the coil paving control line on the base layer.

4. Tear off the separator film and lay it:

Unfold the coil to align the baseline.

Slowly tear off the separation film on the lower surface from one end, roll the coil forward (or backward) at the same time, and immediately roll and exhaust the coil from the middle to both sides with a pressure roller to ensure that the coil and the base layer, and the overlap between the coil and the coil are firmly bonded, without bubbles and wrinkles.

5. Lap Processing:

Long side lap: tear off the separator film of the lap joint (about 60-80mm wide) and directly lap and compact. Some products are designed with a reserved separator film (lap edge separator film), which can be compacted after tearing off.

Short side lap: use butt or lap joint. When docking, it should be covered with a cover strip of the same material not less than 150mm wide, and the bonding surface of the cover strip and the membrane should be compacted and glued firmly after tearing off the film. When lapping, tear off the lap edge separator film and compact it directly.

Lap width: usually the long side lap width ≥ 80mm, and the short side lap width ≥ 100mm (according to the design requirements and product description).

6. End sealing: All end parts of the coil should be mechanically fixed and sealed with special sealing paste or layering.

7. Inspection and repair: After the construction is completed, carefully inspect and repair any bubbles, hollows or damages that are found.

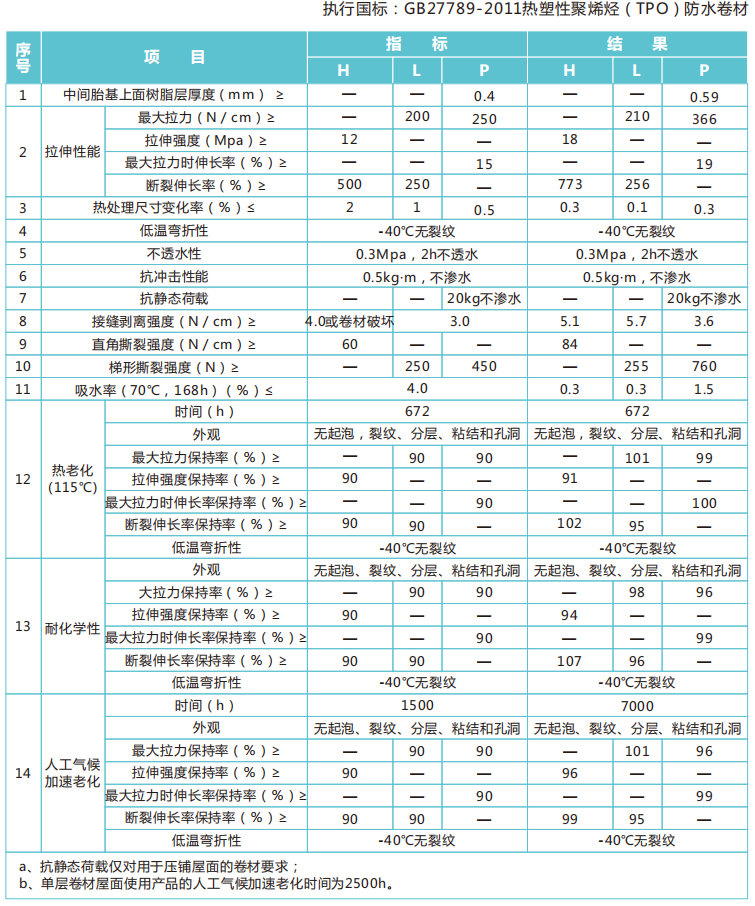

Executive Standard

GB/T 18173.1-2012 "Polymer waterproof membrane"